1%Tungsten Doped Vanadium Dioxide Powder - China Manufacturers, Factory, Suppliers

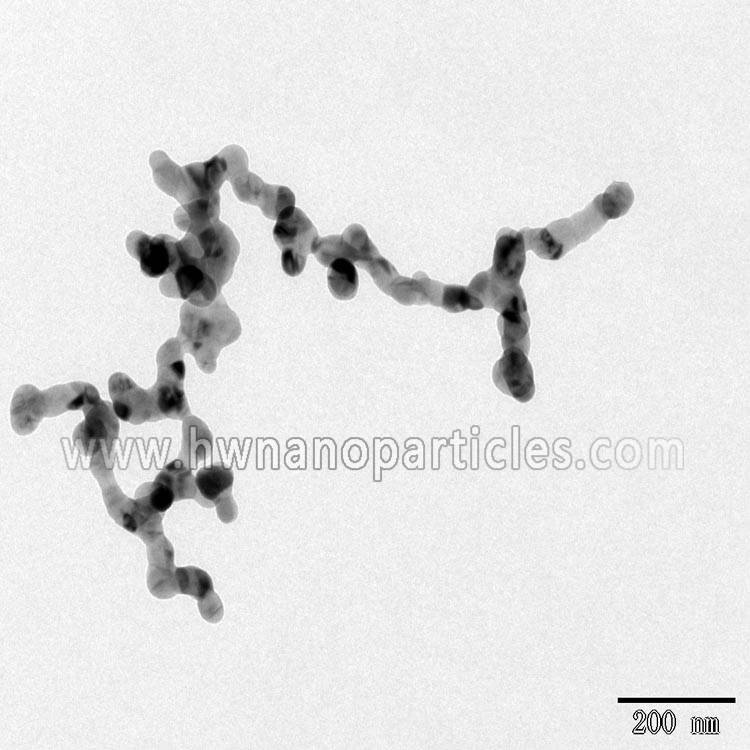

We built a multi-disciplinary team of engineers with backgrounds in chemistry, physics and engineering, and committed to providing quality nanoparticles along with the answers to customer’s questions, concerns and comments. We always looking for ways to better our business and improve our product lines to meet the changing customer demands. 1%Tungsten Doped Vanadium Dioxide Powder, Iron Oxide Nanoparticles , Superfine Silicon Powder , Ni Plated Mwcnts Nano Powder ,Copper Oxide Powder . HONGWU NANO direct factory offer nanoparticles material, reliable nanopowders supplier with favorable factory price. We have nearly 20 years in nanoparticles material manufacture and export. And we are happy that our ultrafine nanopowders material play good effect in different areas for different customers: nano Ag, nano Cu2O, nano CUO, nano ZnO, nano TiO2, silver colloids,copper colloids,etc for antibacterial; nano Au, nano Pd, nano Pt, nano Rh, etc for catalyst; nano ITO, nano ATO, nano Cs0.33WO3, VO2 etc for thermal insulation; nano SiC, nano BN, nano diamond, etc for thermal conductive; Ag silver powders,copper powders, Ag coated Cu, MWCNT, etc for conductive. Application details are always tested by customers, quality nanoparticles raw material and professional service are assured; for great potential projects, we’ll be happy to offer customized solution or have joint research and development with customers. The product will supply to all over the world, such as Europe, America, Australia,Latvia, Morocco,Brasilia, Germany.HONGWU, a world-class nanomaterial manufacturer & supplier, with more than 20 years of experience in the production and export of nanopowders and nanoparticles. Our fit products includes silver series(powders, colloids, dispersions, nanowires, ink) , Precious nanoparticles, PCM(phase-change material) VO2 and W doped VO2, Glass thermal insulation material Cesium doped tungsten oxide, diamond nanoparticles, carbon nanotubes series, oxides and base metal powders etc. Each batch of nanoparticles is extensively characterized using techniques including SEM or TEM, XRD, COA, etc. In addition to ensuring that every batch of nanoparticles meets our stringent quality control requirements, customers are provided with batch-specific specification sheets containing representative SEM/TEM images, Coatings, dispersions, and solution pH.

Related Products