200nm Copper Nanoparticles

200nm copper nanoparticles

Specification:

| Model | A035 |

| Name | cooper nanoparticles |

| Formula | Cu |

| CAS No. | 7440-50-8 |

| Particle Size | 200nm |

| Purity | 99.9% |

| State | dry powder, also wet powder or dispersions are available |

| Appearance | black powder |

| Package | 25g, 50g, 100g, 500g, 1kg in double anti-static bags |

| Potential applications | lubricant, conductive, catalyst, etc. |

Description:

Application of copper nanoparticles:

Metal nano-lubricating additives: add 0.1~0.6% to lubricating oil and grease to form a self-lubricating and self-repairing film on the surface of the friction pair during the rubbing process, which significantly improves the anti-wear and anti-friction performance of the friction pair.

Conductive coating treatment on the surface of metal and non-metal: Nano aluminum, copper, nickel powder has a highly activated surface, and can be coated at a temperature below the melting point of the powder under oxygen-free conditions. This technology can be applied to the production of microelectronic devices.

Efficient catalyst: Copper and its alloy nanopowders are used as catalysts with high efficiency and strong selectivity. They can be used as catalysts in the reaction process of carbon dioxide and hydrogen to methanol.

Conductive paste: used for terminals and internal electrodes of MLCC to miniaturize microelectronic devices. Using it to replace precious metal powders to prepare electronic pastes with superior performance can greatly reduce costs and optimize microelectronic processes.

Raw materials for bulk metal nanomaterials: use inert gas protection powder metallurgy sintering to prepare bulk copper metal nanocomposite structure materials.

Storage Condition:

Copper nanoparticles should be well sealed, stored in 1-5℃ low temperature enviroment.

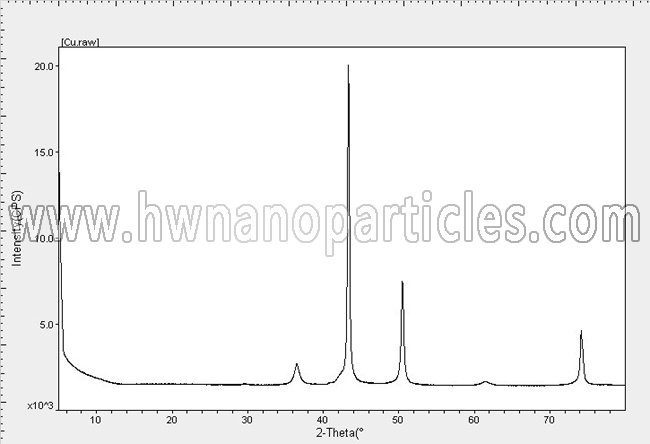

SEM & XRD :