20nm Co nanoparticles deionized water Cobalt wet powder

20nm Co Nanoparticles Deionized Water Cobalt Wet Powder

Specification:

| Code | A050 |

| Name | Cobalt nanoparticles |

| Formula | Co |

| CAS No. | 7440-48-4 |

| Particle Size | 20nm |

| Purity | 99.9% |

| Appearance | black paste |

| MOQ | net Co 100g |

| Package | net Co 100g in well sealed plastic bags |

| Potential applications | Hard alloy material, catalyst, ceramic, etc |

Description:

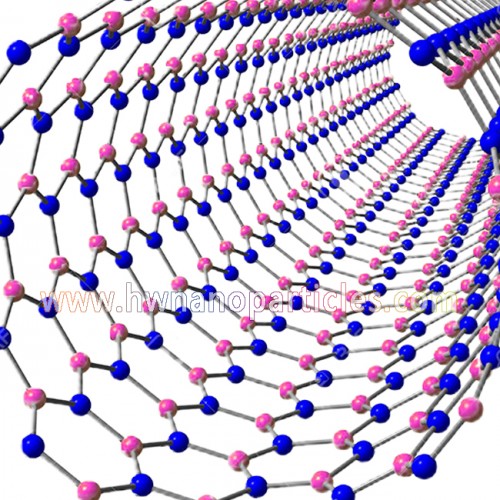

Ultrafine cobalt powder can significantly improve the microstructure of ceramic materials and optimize their performance. Common ceramics are made by fusing various particles together with the help of high temperature and high pressure. After the ultrafine cobalt powder is pressed into a block, due to the high energy of the interface between the particles, it can be sintered at a lower temperature to achieve the purpose of densification, and the performance is excellent, so it is particularly suitable for the preparation of electronic ceramics. The ceramic has strong plasticity, high hardness, high temperature resistance, corrosion resistance, wear resistance and other properties, and the mesh also has high magnetic susceptibility, high coercivity, low saturation magnetic moment, low magnetic loss and light absorption effects.

Ultra-fine cobalt powder also has broad application prospects in the field of building and sanitary ceramics. In addition to being used as ultra-fine slurry, ultra-fine raw material and ultra-fine pigment to improve product quality, it can also bring the following advantages to the traditional sanitary ceramic industry Variety:

①Save energy. After the ceramic raw materials are superfinely pulverized, the surface energy of the particles increases, the activity increases, the driving force for sintering is increased, and the sintering temperature is lowered, thereby achieving the purpose of reducing energy consumption.

②Improve the utilization rate of raw material resources. It is possible to reduce the fineness of the raw materials by increasing the hiding power, so that the low-quality raw materials can achieve the same whiteness as the high-quality raw materials, so as to produce better quality sanitary ceramic products.

③Improve the quality and grade of products. The ultra-fine ceramic material can reduce the sintering temperature of the product, increase the density, and improve the performance of the product, thereby improving the appearance texture and internal quality of the product, and improving the quality and grade of the product.

④Develop high-end new products. Changing the traditional ceramic powder processing technology and developing high-grade new products with high added value is a new hot spot for the application of ultrafine cobalt powder technology in the building and sanitary ceramic industry.

Storage Condition:

20nm Co nanoparticles nano Cobalt wet powder shall be well sealed stored in low temperature enviroment, kindly use it up ASAP once open it, thanks.