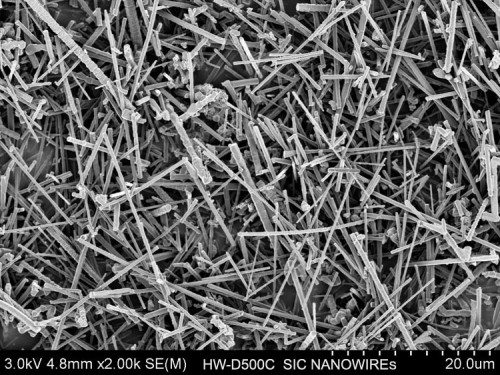

Samar da masana'anta HW-D500C SiCNWs silicon carbide nanowires

Samar da masana'anta HW-D500C SiCNWs silicon carbide nanowires

Bayani:

| Lambar | D500C |

| Suna | Silicon carbide nanowires |

| Formula | SICNWs |

| CAS No. | 409-21-2 |

| Diamita & Tsawon | D <500nm L 50-100um |

| Tsafta | 99% |

| Nau'in Crystal | mai siffar sukari |

| Bayyanar | launin toka kore |

| Kunshin | 10g,50g,100g,200g ko kamar yadda ake bukata |

| Aikace-aikace masu yiwuwa | Ƙarfafawa da ƙarfafa kayan haɗin gwiwa, Ƙarfe matrix da yumbu matrix composites ƙarfafa da ƙarfafa da silicon carbide nanowires an yi amfani da ko'ina a cikin inji, sinadaran masana'antu, kasa tsaro, makamashi, kare muhalli da sauran filayen. |

Bayani:

Kaddarorin jiki na silicon carbide nanowire:

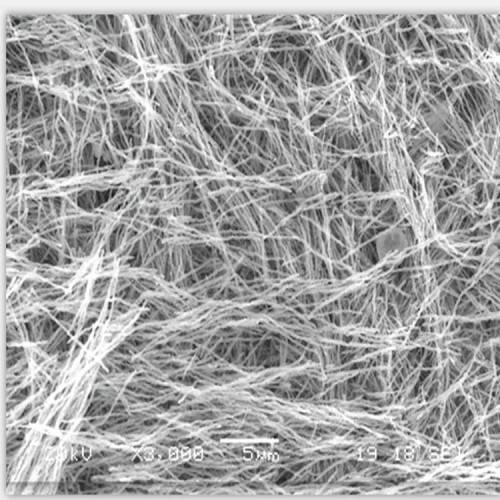

Cubic crystal, wanda shine nau'in crystal mai kama da lu'u-lu'u. Lu'ulu'u ne mai girman girma ɗaya mai girman ƙarfi da siffar gemu. Yana da kyawawan kaddarorin injina da yawa kamar ƙarfin ƙarfi da maɗaukaki mai ƙarfi, wanda shine ɗayan mafi kyawun kayan ƙarfafawa da ƙarfi.

Abubuwan sinadaran silicon carbide nanowires:

Wear juriya, high zafin jiki juriya, musamman girgiza juriya, lalata juriya, radiation juriya.

Babban umarnin aikace-aikacen silicon carbide nanowires:

1.SIC nanowires / yumbu matrix composites: SIC / TIC / WC / ALN / SI3N4 / TIN / AL2O3 / ZRO2 / ZRB2 da dai sauransu

2.SIC nanowires / karfe matrix composites: AL / TI / NI da dai sauransu

3.SIC nanowires / polymer tushen composites: Nylon / guduro / roba / roba da dai sauransu

Watsawa da Ƙarin adadin SiC Nanowires:

Watsawa da Ƙarin adadin SiC Nanowires (don tunani kawai)

Shawarwari watsawa kafofin watsa labarai: deionized ruwa, distilled ruwa, anhydrous ethanol, ethylene glycol

Nagari dispersant: Polyethylene imine (PEI), nonionic polyacry lamide (PAM), sodium pyrophosphate (SPP), twain 80, silicon fili hada guda biyu wakili, polyethylene glycol, sodium hexametaphosphate, sodium carboxymethyl cellulose (CMC), da dai sauransu.

A cikin al'ada yumbu matrix composites, silicon carbide nanowires kasa da 10wt% ana kara gabaɗaya. A cikin aiwatar da takamaiman ingantawa, ana bada shawarar farawa daga 1wt% kuma a hankali gwaji da haɓaka. Bisa ga aikin gwaji, mafi girman adadin ƙarawa ba dole ba ne mafi kyau, yana da alaka da albarkatun kasa, girman kayan aiki, yawan zafin jiki, ma'auni mai mahimmanci zai iya samun sakamako mafi kyau.

Bayan haɗawa da tarwatsawar SiC nanowire slurry da yumbu foda, ci gaba da watse don 1-12 hours. Ana ba da shawarar watsawar dutsen dutse ko hanyar motsawa ta inji. Hanyar niƙa ƙwallon yana da sauƙi don sa nanowires su karye.

Idan hadawar SiC nanowires da kayan matrix ba su da kyau sosai, sodium hexametaphosphate na 1% taro na SiCNW (ko ƙaramin adadin isopropanol/ethanol) za a iya ƙara a matsayin mai watsawa don haɓaka daidaituwar haɗuwa.

Bayan tarwatsa, bushewa da bushewa yakamata a aiwatar da su nan da nan. Zuba slurry a cikin jirgi tare da babban yanki don yada shi na bakin ciki, kuma ƙara yawan yankin zai ƙafe kuma ya bushe cikin sauƙi.Ya fi mahimmanci don kauce wa lalata kayan da aka yi a tsakanin nanowires da matrix. Da shawarar bushewa zafin jiki ne 110-160 ℃.

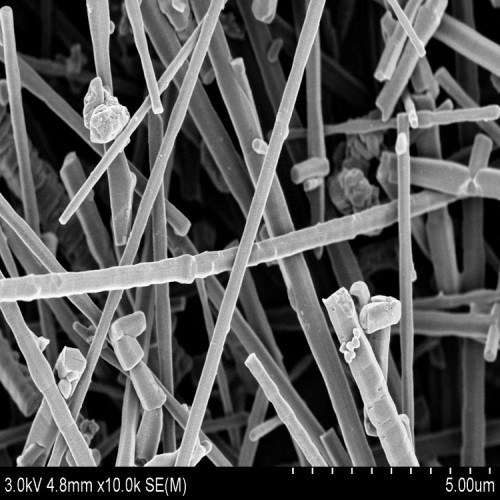

SEM :