Dub Hlau Ni Nickel Nanoparticle Nickel Hmoov

Nickel hmoov specification:

Particle loj: 20nm, 40nm, 70nm, 100nm, 200nm, 500nm, 1-3um

Purity: 99% -99.9%

Xim: Dub / Tsaus Grey

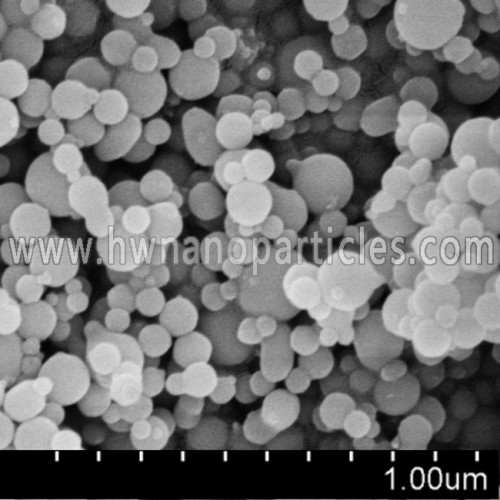

Morphology: Spherical

Cia tej yam kev mob

Cov hlau dub nickel nano hmoov yuav tsum tau muab kaw thiab khaws cia rau hauv qhov chaw qhuav thiab txias. Nano Ni tsis haum kom raug huab cua ntev. nyob rau hauv cov ntaub ntawv agglomeration tshwm sim nyob rau hauv damp, uas cuam tshuam rau dispersion kev ua tau zoo thiab siv tau.

Daim ntawv thov ntawm Nickel hmoov:

1. Cov khoom siv hluav taws xob ua haujlwm siab: Yog tias hloov micron qib nickel hmoov rau hauv nano qib nickel hmoov, thiab nrog cov cuab yeej tsim nyog, nws tuaj yeem tsim tauelectrode nrogthaj chaw loj heev, yog li ntawd qhov tshwj xeeb ntawm thaj chaw cuam tshuam nrog cov nickel hydrogen cov tshuaj tiv thaiv zoo heev, uas ua rau cov nickel hydrogen roj teeb muaj zog ntau zaus, txhim kho kev them nqi thiab kev ua haujlwm zoo.

2. High efficiency catalyst: vim nws qhov loj tshwj xeeb nto thiab kev ua haujlwm siab, nano nickel hmoov muaj cov nyhuv catalytic muaj zog heev. Hloov cov nano nickel hmoov rau cov pa nickel hmoov tuaj yeem txhim kho cov catalytic efficiency thiab tuaj yeem siv rau hydrogenation ntawm cov organic tebchaw. Hauvtsheb tso pa roj kev kho mob, nws tuaj yeem hloov tau cov hlau tseem ceeb platinum thiab rhodium, tus nqi yuav raug txo kom tsawg.

3. Cov kua nplaum nplaum: cov kua nplaum sib nqus ua los ntawm nano npib tsib xee thiab nws cov hmoov hlau alloy muaj kev ua tau zoo heev, uas tuaj yeem siv dav hauv kev sib khi poob siab, cov khoom siv kho mob, cov neeg hais lus siab ncaj ncees, kev tswj xyuas txhua yam thiab lwm yam.

4.Cov khoom siv hluav taws xob: electronic paste yog dav siv nyob rau hauv microelectronics kev lag luam xaim, ntim, kev twb kev txuas, thiab lwm yam, plays lub luag hauj lwm tseem ceeb nyob rau hauv lub miniaturization ntawm microelectronic li.Lub tshuab hluav taws xob slurry ua los ntawm nano npib tsib xee hmoov muaj kev ua tau zoo heev, uas yog qhov zoo rau kev ua kom zoo dua qub ntawm Circuit Court.Nws yog dav siv nyob rau hauv MLCC ntawm ceramic multilayer zaj duab xis capacitance.

5. Activated sintering additives: nano hmoov, vim qhov loj ntawm qhov chaw thiab qhov feem ntawm cov atoms nto, nws muaj lub zog siab zog, thiab muaj zog muaj peev xwm ntawm sintering txawmntawm qhov kub thiab txias, nwsyog ib qho zoo sintering additives, tuaj yeem txo qis heevsintering kub ntawmhmoov metallurgy thiab kub kub ceramic khoom, xws li siv raws li nplaum rau pob zeb diamond thiab ceramic txiav cuab yeej.

6. Non-metallic nto conductive txheej kho: vim lub siab ua kom nto ntawm nano-nickel, txheej txheej tuaj yeem siv rau ntawm qhov kub thiab txias qis dua qhov melting point ntawm cov hmoov nyob rau hauv cov xwm txheej tsis muaj oxygen, txhim kho oxidation kuj, conductivity, corrosion kuj thiab lwm yam kev ua haujlwm khoom ua haujlwm.

7. Cov ntaub ntawv sib nqus: ua kom muaj kev ua haujlwm siab sib nqus cov ntaub ntawv. Cov ntaub ntawv sib nqus ua los ntawm kev sib xyaw nano npib tsib xee nrog lwm cov hmoov hlau tuaj yeem ua rau kom cov ntaub ntawv ceev ceev ntawm cov ntaub nplaum sib nqus thiab tawv & mos disk los ntawm ntau lub sijhawm thiab txhim kho lawv txoj kev ncaj ncees.

8. High efficiency booster: ntxiv nano npib tsib xee hmoov rau cov khoom siv roj hluav taws xob ntawm lub foob pob hluav taws tuaj yeem txhim kho roj combustion kub, combustion efficiency thiab combustion stability.

9. Roj hlwb: nano nickel yog tam sim no ib qho irreplaceable catalyst nyob rau hauv roj hlwb, thiab nws yog siv nyob rau hauv ntau yam roj hlwb (PEM, SOFC, DMFC).Nano-nickel tuaj yeem siv los ua catalyst ntawm cov roj cell los hloov cov platinum kim, uas tuaj yeem txo cov nqi tsim hluav taws xob ntau.Cov electrode nrog thaj tsam loj thiab lub qhov tuaj yeem tsim los ntawm nano nickel hmoov nrog cov cuab yeej tsim nyog, tnws cov khoom siv hluav taws xob ua haujlwm siab tuaj yeem txhim kho kev ua haujlwm tawm.Nws yog ib qho tseem ceeb thiab cov khoom siv tseem ceeb los tsim cov roj hluav taws xob hydrogen.Roj hlwb tuaj yeem siv rau hauv kev ua tub rog, kev ua haujlwm hauv teb, cov Islands tuaj thiab lwm yam khoom siv hluav taws xob ruaj khov. Nws muaj zoo heevthov kev cia siabin kev tiv thaiv ib puag ncig ntsuab txhais tau hais tias kev thauj mus los, lub zog hauv zej zog, lub tsev thiab lub tsev siv hluav taws xob, cua sov thiab lwm yam ntaub ntawv.

10. Cov khoom siv zais cia: siv cov yam ntxwv electromagnetic ntawm nano nickel hmoov, nws yog siv los ua radar stealth khoom thiab electromagnetic shielding khoom nyob rau hauv cov tub rog.

11. Cov khoom siv roj lubricating: nano npib tsib xee hmoov yog ntxiv rau lubricating roj kom txo kev sib txhuam thiab kho qhov kev sib txhuam nto.

Tsuas yog Nickel hmoov, peb tuaj yeem muab koj ntau lwm cov hmoov hlau lossis lawv cov alloy. Xws liAg, Au, Pt, Pd, Rh, Ru, Ge, Al, Zn, Cu, Ti, Sn, W, Ta, Nb, Fe, Co, Cr thiab lwm yam.