Factory supply HW-D500C SiCNWs silicon carbide nanowires

Factory supply HW-D500C SiCNWs silicon carbide nanowires

Specification:

| Code | D500C |

| Lub npe | Silicon carbide nanowires |

| Formula | SICNWs |

| CAS Nr. | 409-21-2 : kuv |

| Diameter & Ntev | D <500nm L 50-100um |

| Purity | 99% |

| Crystal Hom | kub |

| Qhov tshwm sim | grey ntsuab |

| Pob | 10g, 50g, 100g, 200g lossis raws li xav tau |

| Muaj peev xwm siv tau | Cov khoom siv zog thiab toughened composites, Hlau matrix thiab ceramic matrix composites reinforced thiab toughened los ntawm silicon carbide nanowires tau dav siv nyob rau hauv machinery, tshuaj lom neeg kev lag luam, lub teb chaws tiv thaiv, lub zog, ib puag ncig tiv thaiv thiab lwm yam teb. |

Nqe lus piav qhia:

Lub cev muaj zog ntawm silicon carbide nanowire:

Cubic Crystal, uas yog ib hom siv lead ua zoo ib yam li pob zeb diamond. Nws yog ib-dimensional ib leeg siv lead ua muaj zog thiab hwj txwv zoo li. Nws muaj ntau yam khoom siv zoo heev xws li lub zog siab thiab siab modulus, uas yog ib qho zoo tshaj plaws ntxiv dag zog thiab toughening cov ntaub ntawv.

Cov khoom siv tshuaj lom neeg ntawm silicon carbide nanowires:

Hnav tsis kam, kub tsis kam, tshwj xeeb poob siab tsis kam, corrosion kuj, hluav taws xob tsis kam.

Daim ntawv thov tseem ceeb ntawm silicon carbide nanowires:

1.SIC nanowires/ceramic matrix composites: SIC/TIC/WC/ALN/SI3N4/TIN/AL2O3/ZRO2/ZRB2 thiab lwm yam

2.SIC nanowires / hlau matrix composites: AL / TI / NI thiab lwm yam

3.SIC nanowires/polymer raws li composites: Nylon / resin / roj hmab / yas thiab lwm yam

Dispersion thiab Additive npaum li cas ntawm SiC Nanowires:

Dispersion thiab Additive npaum li cas ntawm SiC Nanowires (rau kev siv nkaus xwb)

Pom zoo dispersion media: dej deionized, dej distilled, anhydrous ethanol, ethylene glycol

Pom zoo dispersant: Polyethylene imine (PEI), nonionic polyacry lamide (PAM), sodium pyrophosphate (SPP), twain 80, silicon compound coupling agent, polyethylene glycol, sodium hexametaphosphate, sodium carboxymethyl cellulose (CMC), thiab lwm yam.

Hauv cov khoom siv ceramic matrix zoo tib yam, silicon carbide nanowires tsawg dua 10wt% feem ntau yog ntxiv.Hauv cov txheej txheem ntawm kev ua kom zoo, nws raug nquahu kom pib ntawm 1wt% thiab maj mam sim thiab ua kom zoo dua. Raws li kev sim xyaum, qhov siab dua tus nqi ntxiv tsis tas yuav yog qhov zoo dua, nws muaj feem xyuam rau cov khoom siv raw, cov khoom siv loj, sintering kub, tsim nyog tus nqi ntxiv tuaj yeem tau txais qhov zoo tshaj plaws toughening nyhuv.

Tom qab sib tov cov dispersed SiC nanowire slurry thiab ceramic hmoov, txuas ntxiv mus rau 1-12 teev. hlaws zeb dispersion lossis mechanical stirring txoj kev yog pom zoo. Cov txheej txheem pob milling yog ib qho yooj yim ua rau cov nanowires tawg.

Yog tias qhov sib xyaw ntawm SiC nanowires thiab cov ntaub ntawv matrix tsis zoo, sodium hexametaphosphate ntawm 1% huab hwm coj ntawm SiCNW (los yog ib qho me me ntawm isopropanol / ethanol) tuaj yeem muab ntxiv ua ib qho kev sib cais los txhim kho qhov sib xyaw ua ke.

Tom qab dispersing, qhuav thiab lub cev qhuav dej yuav tsum tau nqa tawm tam sim ntawd. Muab cov slurry tso rau hauv lub nkoj nrog thaj tsam loj kom nws nyias nyias, thiab ua rau thaj chaw yuav evaporate thiab dehydrate yooj yim dua.Nws yog ib qho tseem ceeb kom tsis txhob delamination ntawm raw khoom ntawm nanowires thiab matrix. Qhov pom zoo kom qhuav qhov kub yog 110-160 ℃.

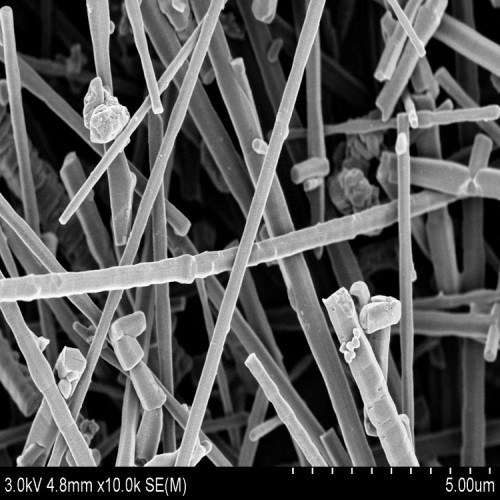

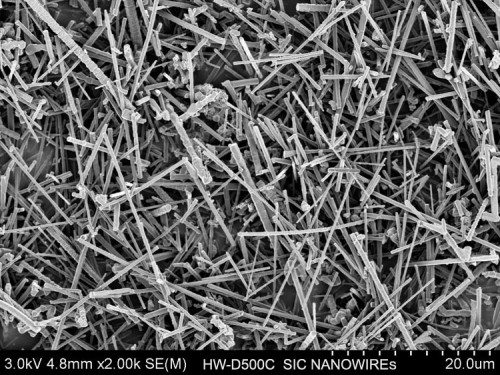

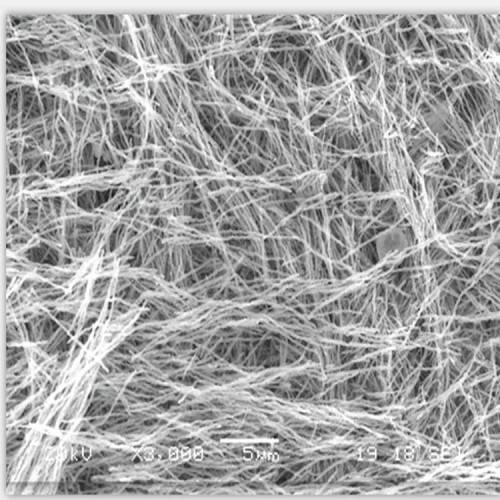

SEM: