Magnesium oxide(MgO Magnesia CAS 1309-48-4) Nanoparticles/Nanopowders

| Index | Stock # R652 MgO | Characterization methods |

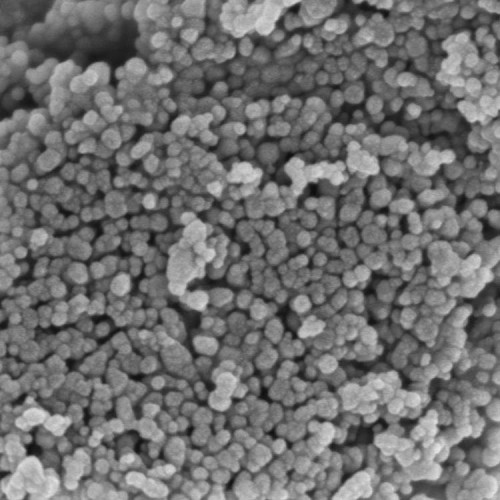

| Particle Size | 30-50nm | TEM Analysis |

| Mophorlogy | Spherical | TEM Analysis |

| Purity | 99.9% | ICP |

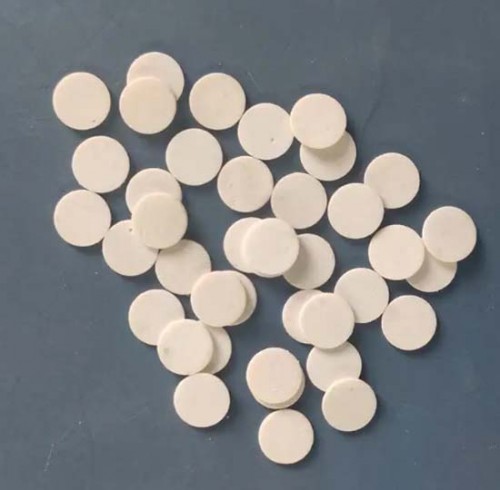

| Appearance | White | Visual Inspection |

| SSA(m2/g) | 30 | BET |

| Packaging | 1kg,5kg,10kg,20kg in bags, barrels, or jumbo bags. | |

| Applications | Rubber, fiber, glass, coatings, adhesives, ceramics, concrete, etc | |

1. Flame retardant

Flame retardant system material is the core of fire retardant coating, and its performance has great influence on the performance of fire retardant coating. Inorganic flame retardants mainly include antimony flame retardants and magnesium flame retardants. Nanometer magnesium oxide, as an excellent flame retardant, has been widely used in the material industry. Its high specific surface area and small particle size enable the nano-magnesia to effectively absorb the heat energy in the combustion products and slow down the flame propagation rate. Therefore, nano magnesium oxide as the main insulating high temperature resistant filling material, is widely used in the flame retardant modification of cables, plastics, rubber, coatings and other products, improving the fire resistance of the material.

2. High-performance ceramic materials

The application of MgO magnesium oxide nanoparticles in ceramic materials has also attracted much attention. Due to its fine particle size and high specific surface area, nano magnesium oxide can increase the compactness and strength of ceramic materials, improve its mechanical properties and wear resistance. In addition, nano magnesium oxide can also improve the thermal conductivity and electrical insulation properties of ceramic materials, so that ceramic materials are widely used in electronic devices, aerospace and other fields.

3. Battery field

MgO Magnesium oxide nanoparticles has potential application prospects in the battery field. As a material with high ionic conductivity, nano magnesium oxide can be used as an additive to battery electrolyte or electrode materials to improve battery performance and cycle stability. In addition, nano magnesium oxide can also be used to prepare new high-performance batteries such as supercapacitors and lithium-ion batteries.

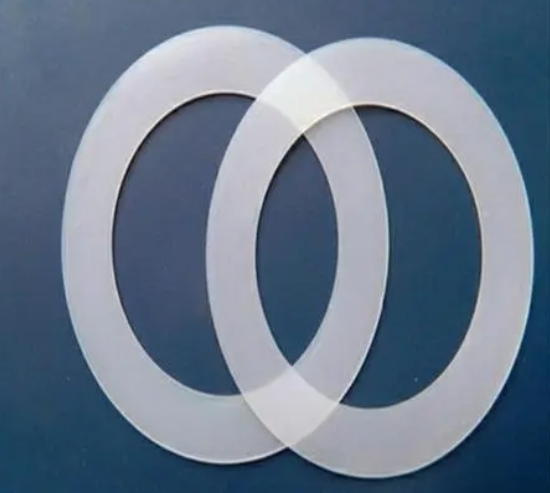

4. Insulation layer and thermal conductivity layer of electronic devices

Because nano magnesium oxide has good insulation and thermal conductivity properties, it is widely used in the insulation layer and thermal conductivity layer of electronic devices. The small particle size and uniform distribution of spherical magnesia powder particles with regular surface morphology can significantly improve the fluidity and dispersion of the powder, and better eliminate the effect of agglomeration on the performance. In the field of integrated circuits, semiconductor devices and other fields, nano magnesium oxide can be used as an insulating layer material to provide electrical isolation and thermal management functions. Mainly used in ceramic, plastic, glass, induction plate, automotive, industrial, wire and cable and other industries.

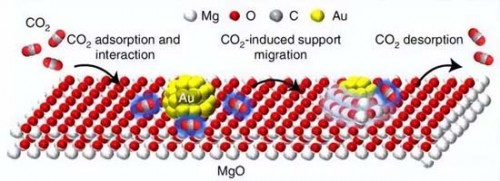

5.Catalyst field

MgO Magnesium oxide nanoparticles also has excellent catalytic performance, can be used as a catalyst directly, and can also be used as a catalyst carrier in catalytic reactions. It can provide high specific surface area and abundant active sites, promote the adsorption of reactive substances and the reaction process, and improve the efficiency and selectivity of catalytic reactions.

6. Rubber and plastic field

Nano magnesium oxide is used in fluorine rubber, neoprene rubber, butyl rubber, chlorinated polyethylene (CPE), polyvinyl chloride (PVC) plastics and adhesives, inks, paints and other aspects. Mainly used as a vulcanization accelerator, filler, anti-coke agent, acid absorbent, fire retardant, wear resistance, corrosion resistance, acid resistance and high temperature resistance and other properties, can improve the working stability under harsh environmental conditions.