Nano Aluminum Particle for Corrosion Resistance - Factory, Suppliers, Manufacturers from China

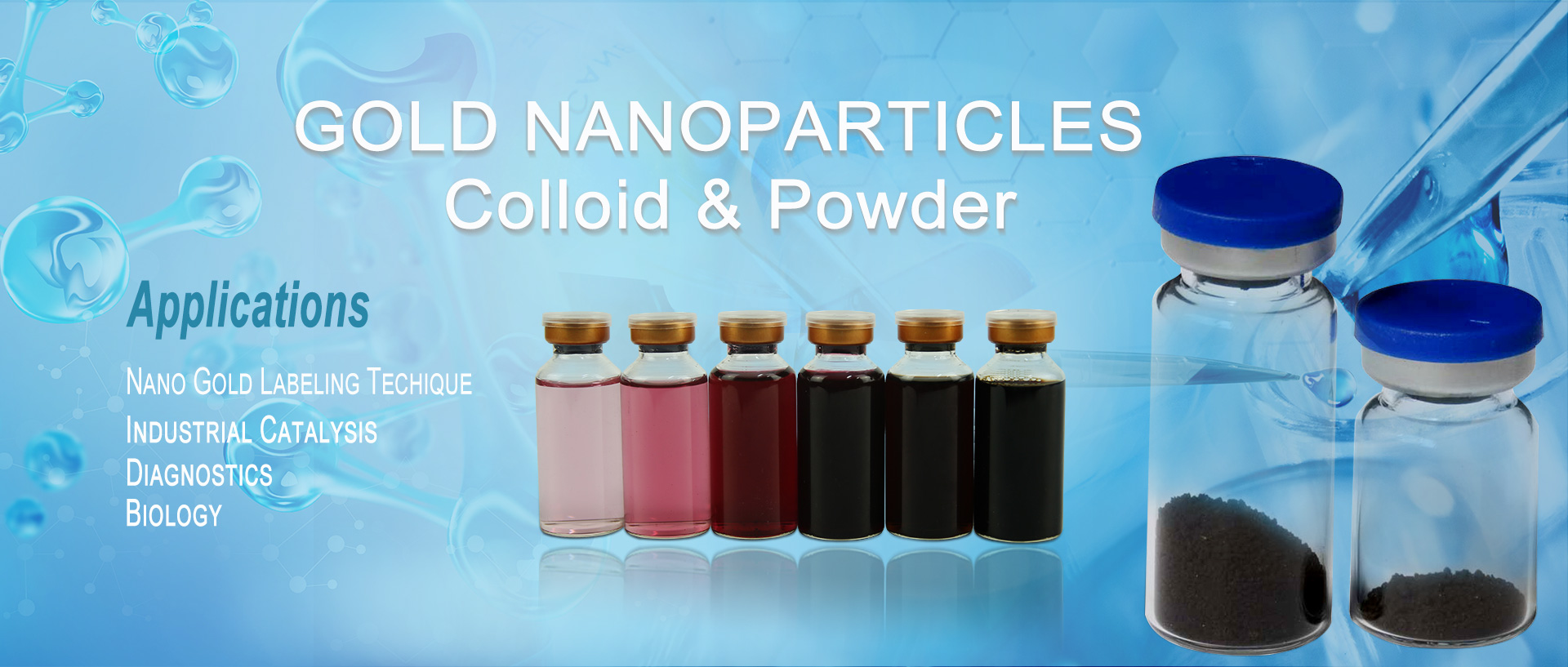

Full Range of nanoparticles application covering antibacterial materials, conductive materials, thermal conductive materials, flexible materials, Nano Aluminum Particle for Corrosion Resistance, Antibacterial Silver Powder , 70nm Tungsten Nanoparticles , 100nm Nickel Nanoparticles ,Nano Silicon Powder . We offer products and service for researchers, distributors and end users at home and abroad. If any need welcome to inquiry! The product will supply to all over the world, such as Europe, America, Australia,Maldives, Cairo,Detroit, South Africa.Hongwu's nanoparticles, nanopowders, colloids, dispersions are used in a variety of applications, including catalysis, Surface Enhanced Raman Spectroscopy, molecular diagnostics,Conductive, Anti-bacteria, anti-ultraviolet,Reinforced, thermal insulation, polishing, wave absorbing, battery,etc. Element & oxides & compound & carbon family nanopowders & nanowires/nanotubes/nanorods. Particle sizes are from 5nm up to 20um in diameter and custom surface functionalizations are available upon request. The materials could be delivered to all over the world, such as Europe, America, Australia, South Africa, Japan, Korea, Singapore, India, Israel, etc. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle. All of our core technical team members have 15+ years experience in R&D and production. Our sales, business operations and logistics teams are staffed with experienced professionals to provide friendly and timely support and services to our customers.

Related Products