Thermally conductive plastics refer to a type of plastic products with higher thermal conductivity, usually with a thermal conductivity greater than 1W/(m . K). Most metal materials have good thermal conductivity and can be used in radiators, heat exchange materials, waste heat recovery, brake pads and printed circuit boards. However, the corrosion resistance of metal materials is not good, which limits the application in some fields, such as heat exchangers, heat pipes, solar water heaters and battery coolers in chemical production and wastewater treatment. The corrosion resistance and mechanical properties of plastics are very good, but compared with metal materials, the thermal conductivity of plastic materials is not good. The thermal conductivity of HDPE with the best thermal conductivity is only 0.44VV/(m . K). The low thermal conductivity of plastic limits its scope of application, such as not being used in all kinds of frictional heat generation or occasions requiring timely heat dissipation.

With the rapid development of integration technology and assembly technology in the electrical field, the volume of electronic components and logic circuits has shrunk thousands and tens of thousands of times, and there is an urgent need for insulating packaging materials with high heat dissipation. The addition of high-purity ultra-fine nano-magnesium oxide can meet this demand. It can be used for thermally conductive plastics, thermally conductive resin castables, thermally conductive silica gel, thermally conductive powder coatings, functional thermally conductive coatings and various functional polymer products. It is used in PA, PBT, PET, ABS, PP, as well as in organic silica gel, coatings and other materials to play a thermal role.

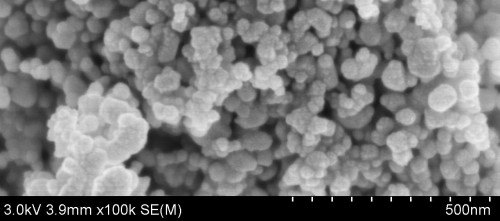

In the matrix resin with high crystallinity, adding high thermal conductivity additives is the most effective way to improve the thermal conductivity of plastics. Refinement of the thermal conductive filler, even nano-size, not only has a small impact on the mechanical properties, but also improves the thermal conductivity; the addition of high-purity nano-magnesium oxide has a small particle size and uniform particle size, and the thermal conductivity is reduced from the ordinary 33W/(m.K). ) Is increased to above 36W/(m . K).

Experiments show that adding 80% of high-purity nano magnesium oxide MgO to PPS can achieve a thermal conductivity of 3.4W/m.K; adding 70% of aluminum oxide can achieve a thermal conductivity of 2.392W/m.K.

Adding 10% of high-purity nano MgO magnesium oxide to the EVA solar encapsulant film improves the thermal conductivity, and the insulation, cross-linking degree and thermal stability are also improved to varying degrees. There is a critical value for the amount of thermally conductive material added.

Thermally conductive plastics can be used in central air conditioning systems, solar water heaters, building heating pipes, heat transfer materials for chemical corrosive media, soil heaters, commercial instruments, automation equipment, gears, bearings, gaskets, mobile phones, electronic devices, generator covers And lampshades and other occasions. Thermally conductive plastics are mainly used in heat exchange engineering such as radiators, heat exchange tubes, etc., and heat dissipation of electronic components such as circuit boards and LED packaging materials. The uses are extremely wide, and the prospects are great.

Post time: Apr-01-2022