200nm Copper Nanoparticles

200nm mhangura nanoparticles

Tsanangudzo:

| Model | A035 |

| Zita | Cooper nanoparticles |

| Formula | Cu |

| CAS Nha. | 7440-50-8 |

| Particle Size | 200nm |

| Kuchena | 99.9% |

| State | hupfu hwakaoma, zvakare hupfu hwakanyorova kana kupararira zviripo |

| Chitarisiko | hupfu dema |

| Package | 25g, 50g, 100g, 500g, 1kg mumabhegi maviri anti-static |

| Zvingango shandiswa | lubricant, conductive, catalyst, nezvimwe. |

Tsanangudzo:

Kushandiswa kwemhangura nanoparticles:

Metal nano-lubricating additives: wedzera 0.1 ~ 0.6% kumafuta ekuzora uye girisi kuti uite firimu rinozvizora uye rinozvigadzirisa pamusoro peiyo friction pair panguva yekukwesha, iyo inovandudza zvakanyanya anti-kupfeka uye anti-friction. kuita kweiyo friction pair.

Conductive coating treatment pamusoro pesimbi uye isiri-metal: Nano aluminium, mhangura, nickel poda ine nzvimbo yakashandiswa zvikuru, uye inogona kuvharwa pakupisa pazasi pekunyungudika kwehupfu pasi pemamiriro asina oxygen. Iyi tekinoroji inogona kushandiswa pakugadzira michina yemicroelectronic.

Inoshanda catalyst: Mhangura uye ayo alloy nanopowders anoshandiswa seanokonzeresa ane hunyanzvi hwepamusoro uye sarudzo yakasimba. Zvinogona kushandiswa sezvinokonzeresa mukuita kwekabhoni dhaidhisiki uye hydrogen kune methanol.

Conductive paste: inoshandiswa kumaterminals uye emukati maelectrodes eMLCC kuita miniaturize microelectronic zvishandiso. Kuishandisa kutsiva yakakosha simbi hupfu kugadzirira paste yemagetsi nekuita kwepamusoro kunogona kuderedza zvakanyanya mutengo uye optimize microelectronic maitiro.

Raw zvinhu zveakawanda simbi nanomaterials: shandisa inert gasi kudzivirira poda metallurgy sintering kugadzirira yakawanda mhangura simbi nanocomposite chimiro zvinhu.

Storage Condition:

Copper nanoparticles inofanira kunge yakavharwa zvakanaka, yakachengetwa mu1-5 ℃ yakaderera tembiricha nharaunda.

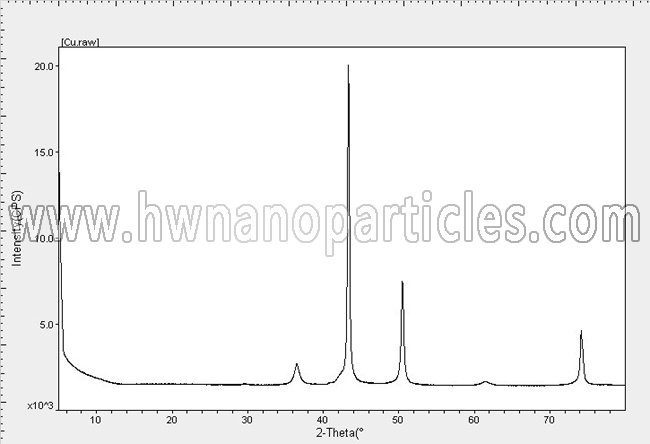

SEM & XRD :

Tumira meseji yako kwatiri:

-

Phone

-

E-mail

-

WhatsAPP

-

Wechat

Wechat

-

Skype

Skype