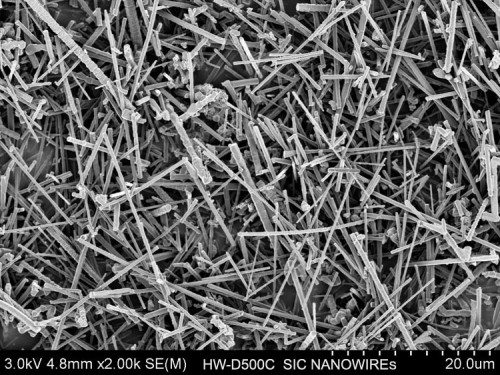

Sahayda warshada HW-D500C SiCNWs silicon carbide nanowires

Sahayda warshada HW-D500C SiCNWs silicon carbide nanowires

Faahfaahin:

| Koodhka | D500C |

| Magaca | Silicon carbide nanowires |

| Formula | SICNWs |

| CAS Maya. | 409-21-2 |

| Dhexroorka & Dhererka | D <500nm L 50-100um |

| daahirnimo | 99% |

| Nooca Crystal | cubic |

| Muuqashada | cagaar cawlan |

| Xidhmada | 10g,50g,100g,200g ama sida loo baahan yahay |

| Codsiyada suurtagalka ah | Qalabka isku-dhafka ah ee la xoojiyay iyo kuwa la adkeeyay, Matrix-yada birta iyo isku-dhafka dhoobada dhoobada ah ee la xoojiyay laguna adkeeyay silikoon carbide nanowires ayaa si weyn loogu isticmaalay mishiinka, warshadaha kiimikada, difaaca qaranka, tamarta, ilaalinta deegaanka iyo qaybaha kale. |

Sharaxaad:

Astaamaha jireed ee silicon carbide nanowire:

crystal cubic, kaas oo ah nooc ka mid ah crystal la mid ah dheeman. Waa crystal hal-gees ah oo leh xoog sare iyo qaab gadh. Waxay leedahay sifooyin farsamo oo badan oo aad u wanaagsan sida xoog sare iyo modules sare, taas oo ah mid ka mid ah qalabka ugu fiican ee xoojinta iyo adkaynta.

Sifooyinka kiimikaad ee silikoon carbide nanowires:

Xiro caabbinta, caabbinta heerkulka sare, caabbinta shoogga gaarka ah, iska caabinta daxalka, iska caabinta shucaaca.

Tilmaamaha codsiga muhiimka ah ee nanowires silicon carbide:

1.SIC nanowires / dhoobada matrix isku dhafan: SIC / TIC / WC / ALN / SI3N4 / TIN / AL2O3 / ZRO2 / ZRB2 iwm

2.SIC nanowires/metal matrix composites:AL/TI/NI iwm

3.SIC nanowires/polymer-ku-salaysan isku-dhafka: nylon / resin / caag / caag iwm

Kala firdhinta iyo qadarka lagu daro ee SiC Nanowires:

Kala firdhinta iyo qadarka lagu daro ee SiC Nanowires (tixraac kaliya)

Warbahinta kala firdhisan ee lagu taliyay: biyaha la miiray, biyo la miiray, ethanol anhydrous, glycol ethylene

Kala firdhinta lagu taliyay: Polyethylene imine (PEI), polyacry lamide nonionic (PAM), sodium pyrophosphate (SPP), twain 80, wakiilka isku dhafka silicon, polyetylen glycol, sodium hexametaphosphate, sodium carboxymethyl cellulose (CMC), iwm.

Isku-dhafka dhoobada caadiga ah ee dhoobada, silicon carbide nanowires in ka yar 10wt% ayaa guud ahaan lagu daraa. Habka hagaajinta gaarka ah, waxaa lagula talinayaa in laga bilaabo 1wt% oo si tartiib tartiib ah u tijaabiso oo u wanaajiso. Marka loo eego dhaqanka tijaabada ah, tirada sare ee kordhinta ma aha daruuri ka wanaagsan, waxay la xiriirtaa alaabta ceeriin, cabbirka alaabta, heerkulka sintay, qadar macquul ah oo lagu daro waxay heli kartaa saameynta ugu fiican ee adag.

Ka dib marka la isku daro SiC nanowire slurry iyo budada dhoobada ah ee kala firdhiyey, sii wad inaad kala firdhiso 1-12 saacadood. kala firdhiso ul kuul ama habka walaaq ee farsamada ayaa lagula talinayaa. Habka wax-shiididdu waa sahlan tahay in nanowires-ka ay jebiyaan.

Haddii isku darka SiC nanowires iyo qalabka matrixka ah aysan aad u fiicneyn, sodium hexametaphosphate ee 1% baaxadda SiCNW (ama qadar yar oo isopropanol/ethanol) ayaa lagu dari karaa kala firdhiso si loo hagaajiyo isku-dhafka isku dhafka ah.

Ka dib marka la kala firdhiyo, qallayl iyo fuuqbax waa in isla markiiba la sameeyaa. Ku shub dareeraha weel leh aag weyn si aad u faafiso dhuuban, kordhiyana aagga ayaa uumi bixi doonaa oo si fudud u fuuqbaxa. Waxaa aad muhiim u ah in laga fogaado delamination ee alaabta ceeriin ee u dhexeeya nanowires iyo matrixka. Heerkulka lagu taliyey ee qalajinta waa 110-160 ℃.

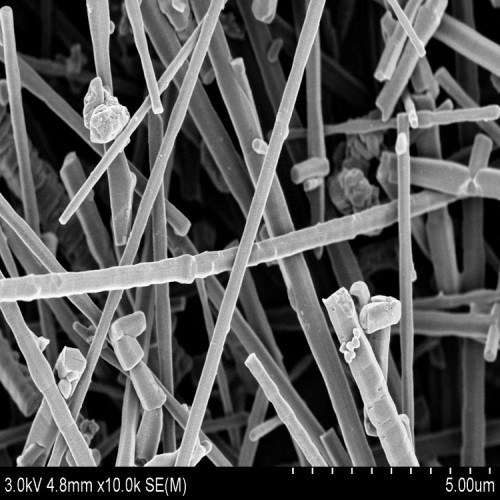

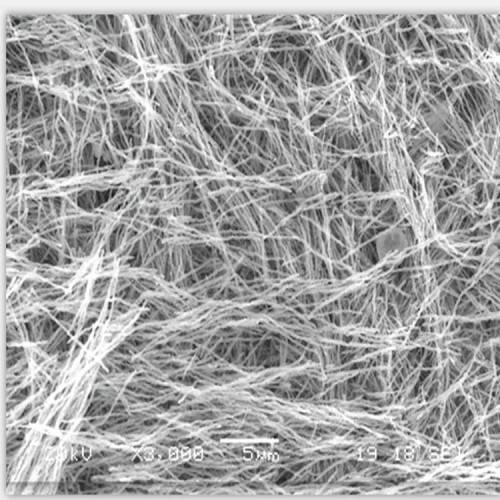

SEM