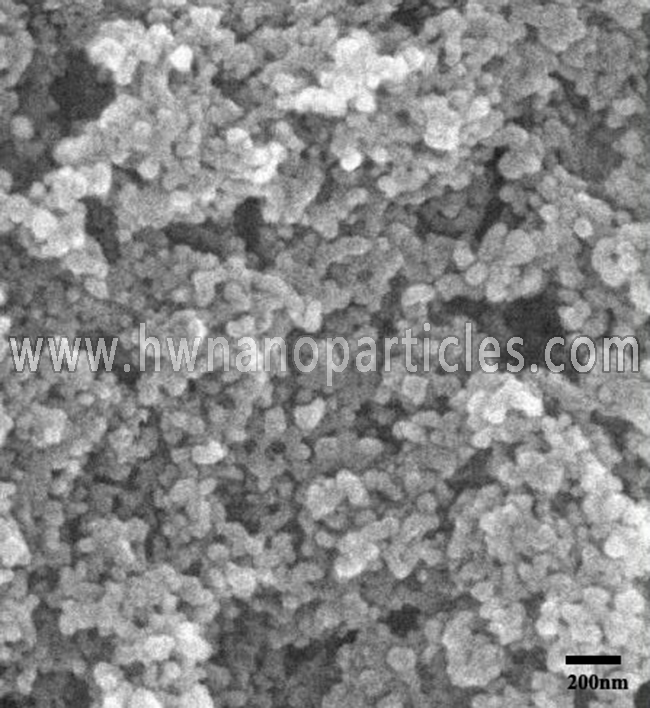

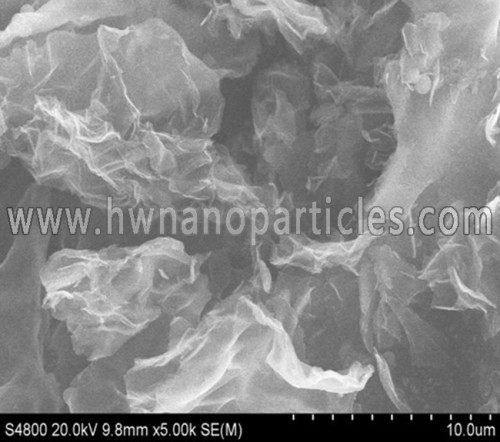

80-100nm Nano Diamond Powder

Nano Diamond Powder

Inkcazo:

| Ikhowudi | C962 |

| Igama | Nano Diamond Powder |

| Ifomula | C |

| Inombolo yeCAS. | 7782-40-3 |

| Ubungakanani beNcam | 80-100nm |

| Ubunyulu | 99% |

| Imbonakalo | Ngwevu |

| Obunye ubungakanani | 10nm, 30-50nm |

| Iphakheji | 1kg/ibhegi okanye njengoko kufuneka |

| Usetyenziso olunokwenzeka | Ukucoliseka okuchanekileyo kunye nokuthambisa, i-catalysis yeekhemikhali, i-composite coating |

Inkcazo:

Isetyenziselwa ukwenza irabha eyomeleziweyo kunye neresin eqinisiweyo.Esi sicelo sineempembelelo ezicacileyo ekuphuculeni i-thermal conductivity yezinto eziphathekayo, ukushisa kwe-polymer degradation, amandla kunye nokumelana nokunxiba.Inokunyusa amandla ayo ngamaxesha angama-1 ukuya kwe-4 kwaye iphucule kakhulu ukuxhatshazwa kwayo kunye nokuqina.

I-Nano-diamond composite coating inobunzima obukhulu, ukumelana nokunxiba okuphezulu, ukumelana nobushushu kunye nokumelana nomhlwa, kwaye ingasetyenziselwa ukugquma imiphezulu yesinyithi kunye nerabha, iplastiki, iglasi kunye nezinye iindawo.I-Nano-composite plating matrix ikakhulu ibandakanya i-nickel, i-cobalt, i-cobalt, njl njl. I-nickel-plated layer equkethe i-nano-diamond isetyenziswe njengoluhlu olukhuselayo olukhuselayo kwiidiski okanye iintloko zemagneti.Xa kuthelekiswa ne-plating eqhelekileyo, ubunzima bayo bunyuke nge-50%, kwaye ukuchasana kwayo kunyuke kakhulu..

Iglasi yokukhanya enefilimu ekhuselayo ye-nano-diamond inokuphucula kakhulu amandla eglasi yokumelana nokhukuliseko lwemvula, ukhukuliseko lwesanti, kunye nokukrwela phantsi kweemeko ezimandundu, nakwindawo yobushushu obuphezulu kunye nemitha, efana nokulungiswa komjukujelwa.Isigqubuthelo sinokusebenzisa ifilimu ye-nano-diamond yokukhusela.Ukongeza, ifilimu ye-nano-diamond ineempawu ezibalaseleyo ze-electrochemical kunye nelahleko ephantsi kakhulu ye-dielectric, ngoko inokusetyenziswa njengefestile yeetyhubhu ze-microwave ezinamandla aphezulu.Ukusuka kulo mbono, ifilimu ye-nano-diamond ngokungathandabuzekiyo ibe lukhetho oluhle kakhulu kwicala lophuhliso lwesikhokelo somjukujelwa njengesikhokelo se-microwave kunye nesikhokelo se-infrared.

Ukongezwa kwedayimani ye-nano akugcini nje ukunyusa i-microhardness yokwambathisa, i-impembelelo-resistant kunye ne-scratch-resistant, kodwa ikwanebhondi eyomeleleyo kunye ne-substrate, kwaye iphucula kakhulu ukuxhathisa kwe-corrosion, ukuxhathisa kwamanzi kunye ne-thermal conductivity.

Imeko yoGcino:

I-Nano powder powder kufuneka igcinwe kwindawo evaliweyo, igweme ukukhanya, indawo eyomileyo.Ukugcinwa kobushushu begumbi kulungile.

I-SEM: