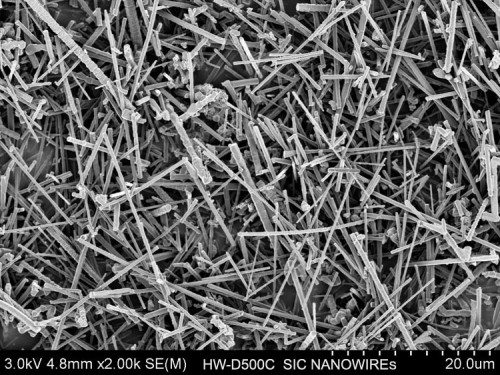

Ipese Factory HW-D500C SiCNWs silikoni carbide nanowires

Ipese Factory HW-D500C SiCNWs silikoni carbide nanowires

Ni pato:

| Koodu | D500C |

| Oruko | Silikoni carbide nanowires |

| Fọọmu | SICNWs |

| CAS No. | 409-21-2 |

| Iwọn & Gigun | D <500nm L 50-100um |

| Mimo | 99% |

| Crystal Iru | onigun |

| Ifarahan | alawọ ewe grẹy |

| Package | 10g,50g,100g,200g tabi bi beere |

| Awọn ohun elo ti o pọju | Imudara ati awọn ohun elo idapọmọra ti o ni lile, Matrix irin ati awọn akojọpọ matrix seramiki ti a fikun ati ti o ni agbara nipasẹ ohun alumọni carbide nanowires ti ni lilo pupọ ni ẹrọ, ile-iṣẹ kemikali, aabo orilẹ-ede, agbara, aabo ayika ati awọn aaye miiran. |

Apejuwe:

Awọn ohun-ini ti ara ti silicon carbide nanowire:

Kirisita onigun, eyiti o jẹ iru gara ti o jọra si diamond. O jẹ kristali onisẹpo kan pẹlu agbara giga ati apẹrẹ irungbọn. O ni ọpọlọpọ awọn ohun-ini ẹrọ ti o dara julọ gẹgẹbi agbara giga ati modulus giga, eyiti o jẹ ọkan ninu awọn ohun elo imudara ti o dara julọ ati toughing.

Awọn ohun-ini kemikali ti silicon carbide nanowires:

Wọra resistance, iwọn otutu giga, resistance mọnamọna pataki, resistance ipata, resistance itankalẹ.

Awọn itọnisọna ohun elo akọkọ ti silicon carbide nanowires:

1.SIC nanowires / seramiki matrix composites: SIC / TIC / WC / ALN / SI3N4 / TIN / AL2O3 / ZRO2 / ZRB2 ati be be lo

2.SIC nanowires/metal matrix composites:AL/TI/NI etc

3.SIC nanowires / polima orisun apapo: Nylon / resini / roba / ṣiṣu ati be be lo

Pipin ati afikun iye SiC Nanowires:

Pipin ati iye afikun ti SiC Nanowires (fun itọkasi nikan)

Awọn media pipinka ti a ṣe iṣeduro: omi ti a ti sọ dio, omi distilled, ethanol anhydrous, ethylene glycol

Niyanju dispersant: Polyethylene imine (PEI), nonionic polyacry lamide (PAM), sodium pyrophosphate (SPP), twain 80, ohun alumọni compounding oluranlowo, polyethylene glycol, sodium hexametaphosphate, sodium carboxymethyl cellulose (CMC), ati be be lo.

Ninu awọn akojọpọ seramiki seramiki lasan, silikoni carbide nanowires ti o kere ju 10wt% ni a ṣafikun ni gbogbogbo.Ninu ilana ti iṣapeye kan pato, o gba ọ niyanju lati bẹrẹ lati 1wt% ki o ṣe idanwo diẹdiẹ ati imudara. Gẹgẹbi adaṣe adaṣe, iye ti o ga julọ kii ṣe dandan dara julọ, o ni ibatan si ohun elo aise, iwọn ohun elo, iwọn otutu sintering, iye afikun oye le gba ipa toughing ti o dara julọ.

Lẹhin ti o dapọ SiC nanowire slurry ti a tuka ati lulú seramiki, tẹsiwaju lati tuka fun awọn wakati 1-12. Ilẹkẹ ọlọ pipinka tabi darí saropo ọna ti wa ni niyanju. Ọna milling rogodo jẹ rọrun lati fa awọn nanowires lati fọ.

Ti didapọ awọn SiC nanowires ati awọn ohun elo matrix ko dara bẹ, iṣuu soda hexametaphosphate ti 1% ibi-pupọ ti SiCNW (tabi iye kekere ti isopropanol/ethanol) ni a le ṣafikun bi kaakiri lati mu isokan idapọpọ pọ si.

Lẹhin ti tuka, gbẹ ati gbigbẹ yẹ ki o ṣee ṣe lẹsẹkẹsẹ. Tú slurry sinu ọkọ oju omi pẹlu agbegbe nla lati tan kaakiri, ati pe agbegbe naa yoo yọ kuro ati ki o gbẹ ni irọrun. Iwọn otutu ti a ṣe iṣeduro jẹ 110-160 ℃.

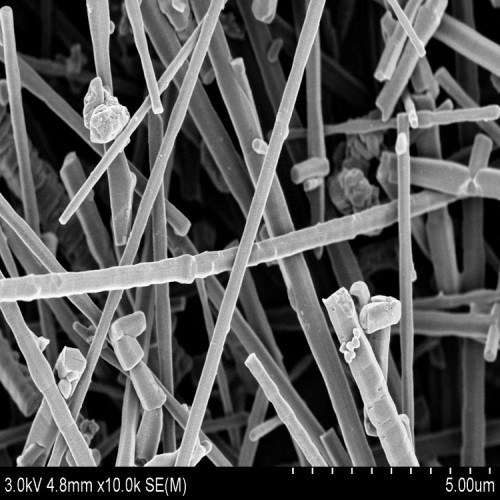

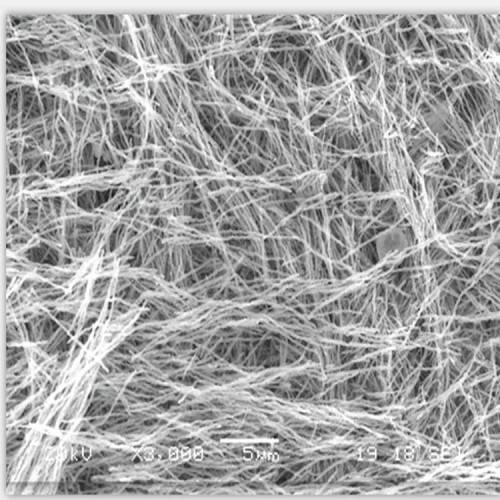

SEM: