I-200nm yethusi Nanoparticles

200nm yethusi nanoparticles

Ukucaciswa:

| Imodeli | A035 |

| Igama | i-cooper nanoparticles |

| Ifomula | Cu |

| Inombolo ye-CAS. | 7440-50-8 |

| Usayizi Wezinhlayiyana | 200nm |

| Ubumsulwa | 99.9% |

| Izwe | impushana eyomile, nayo impushana emanzi noma ama-dispersions ayatholakala |

| Ukubukeka | impushana emnyama |

| Iphakheji | 25g, 50g, 100g, 500g, 1kg emasakeni anti-static kabili |

| Izinhlelo zokusebenza ezingaba khona | i-lubricant, i-conductive, i-catalyst, njll. |

Incazelo:

Ukusetshenziswa kwe-nanoparticles yethusi:

Izithasiselo ze-Metal nano-lubricating: engeza u-0.1 ~ 0.6% kuwoyela wokugcoba namafutha ukuze wenze ifilimu ezigcobayo nezizilungisayo ebusweni bepheya yokungqubuzana phakathi nenqubo yokuhlikihla, okuthuthukisa kakhulu ukulwa nokugqokwa nokulwa nokungqubuzana. ukusebenza kwe-friction pair.

Ukwelashwa kwe-conductive coating ebusweni bensimbi nokungeyona insimbi: I-Nano aluminium, ithusi, i-nickel powder inendawo esebenza kakhulu, futhi ingafakwa ekushiseni okungaphansi kwendawo yokuncibilika kwe-powder ngaphansi kwezimo ezingenawo umoya-mpilo.Lobu buchwepheshe bungasetshenziswa ekukhiqizeni amadivaysi e-microelectronic.

I-catalyst ephumelelayo: I-Copper ne-alloy nanopowder yayo isetshenziswa njengama-catalysts ngokusebenza kahle okuphezulu kanye nokukhetha okunamandla.Angasetshenziswa njengama-catalysts enqubweni yokusabela kwe-carbon dioxide ne-hydrogen ku-methanol.

I-conductive paste: isetshenziselwa amatheminali nama-electrode angaphakathi e-MLCC ukuze kuncishiswe amadivaysi e-microelectronic.Ukuwusebenzisa esikhundleni sezimpushana zensimbi eyigugu ukuze ulungise ukunamathisela kwe-elekthronikhi ngokusebenza okuphakeme kunganciphisa kakhulu izindleko futhi kuthuthukise izinqubo ze-microelectronic.

Izinto ezingasetshenzisiwe zenqwaba ye-nanomaterials yensimbi: sebenzisa i-inert gas protection powder metallurgy sintering ukuze ulungise izinto zokwakha zensimbi yethusi nanocomposite.

Isimo Sesitoreji:

I-nanoparticles yethusi kufanele ivalwe kahle, igcinwe endaweni engaphansi kwe-1-5 ℃.

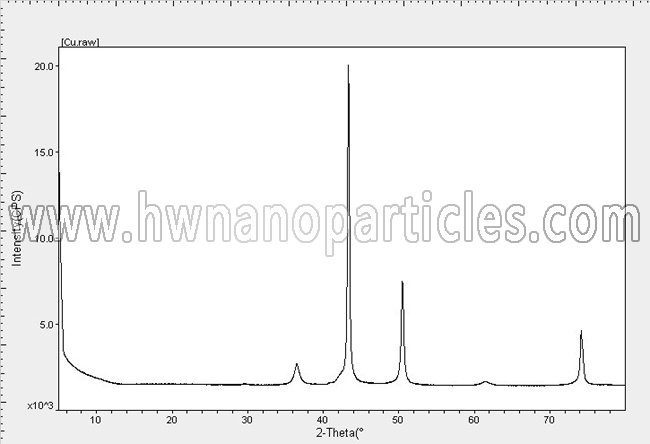

I-SEM ne-XRD :