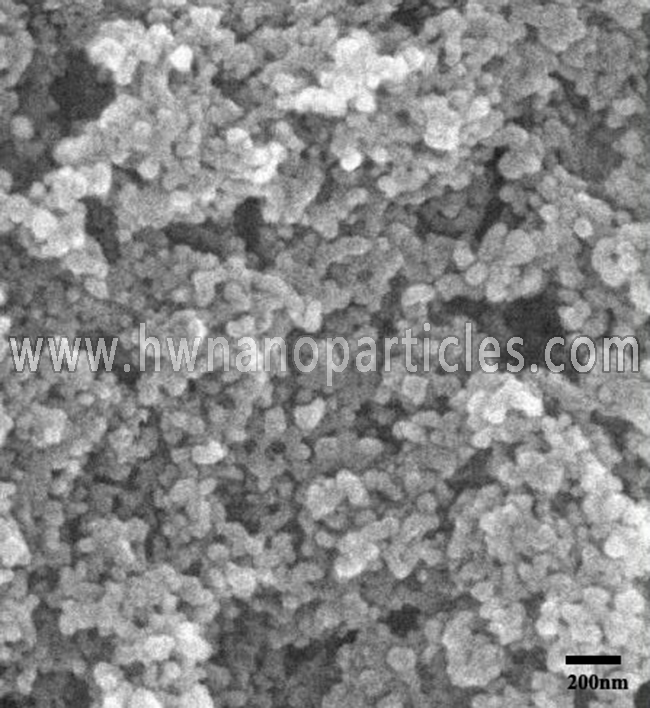

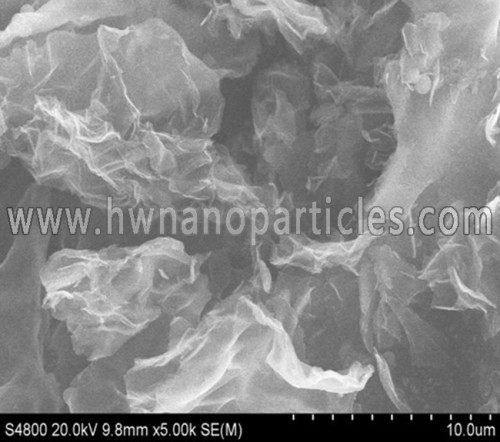

80-100nm Nano Diamond Powder

I-Nano Diamond powder

Ukucaciswa:

| Ikhodi | C962 |

| Igama | I-Nano Diamond powder |

| Ifomula | C |

| Inombolo ye-CAS. | 7782-40-3 |

| Usayizi Wezinhlayiyana | 80-100nm |

| Ubumsulwa | 99% |

| Ukubukeka | Okumpunga |

| Omunye usayizi | 10nm, 30-50nm |

| Iphakheji | 1kg/isikhwama noma njengoba kudingeka |

| Izinhlelo zokusebenza ezingaba khona | Ukunemba kokupholisha kanye nokugcoba, i-chemical catalysis, ukunamathela okuyinhlanganisela |

Incazelo:

Isetshenziselwa ukwenza irabha eqinisiwe kanye ne-resin eqinisiwe.Lolu hlelo lokusebenza lunemiphumela esobala ekuthuthukiseni i-thermal conductivity yezinto zokwakha, izinga lokushisa le-polymer degradation, amandla kanye nokumelana nokugqoka.Ingakwazi ukwandisa amandla ayo ngo-1 izikhathi ezingu-4 futhi ithuthukise kakhulu ukumelana kwayo nokugqoka kanye nokuqina.

I-Nano-diamond composite coating ine-super hard, high ukuguga ukumelana, ukumelana nokushisa nokumelana nokugqwala, futhi ingasetshenziselwa ukumboza izindawo zensimbi nenjoloba, ipulasitiki, ingilazi nezinye izindawo.I-Nano-composite plating matrix ikakhulukazi ihlanganisa i-nickel, ithusi, i-cobalt, njll. Ungqimba oluhlanganisiwe lwe-nickel-plated oluqukethe i-nano-diamond lusetshenziswa njengesendlalelo sokuvikela esingagugi samadiski noma amakhanda kazibuthe.Uma kuqhathaniswa ne-plating evamile, ubulukhuni bayo bukhuphuke ngo-50%, futhi ukumelana kwayo nokugqoka kuye kwanda kakhulu..

Ingilazi ebonakalayo enefilimu yokuvikela ye-nano-diamond ingathuthukisa kakhulu ikhono lengilazi yokubona ukumelana nokuguguleka kwemvula, ukuguguleka kwesihlabathi, nokuklwebheka ngaphansi kwezimo ezimbi kakhulu, ngisho nasezindaweni zokushisa eziphezulu kanye nemisebe, njengokulungiswa kwemicibisholo.Ikhava ingasebenzisa ifilimu ye-nano-diamond ukuze ivikeleke.Ngaphezu kwalokho, ifilimu ye-nano-diamond nayo inezindawo ezinhle kakhulu ze-electrochemical kanye nokulahlekelwa kwe-dielectric ephansi kakhulu, ngakho-ke ingasetshenziswa njengefasitela lamashubhu we-microwave enamandla amakhulu.Kusukela kuleli phuzu lokubuka, ifilimu ye-nano-diamond ngokungangabazeki isibe yisinqumo esihle kakhulu ekuthuthukisweni kokuqondisa kwemicibisholo njengokuqondiswa kwe-microwave kanye nesiqondiso se-infrared.

Ukwengezwa kwedayimane le-nano akugcini nje ukwandisa ukuqina kwe-microhardness ye-coating, kunamandla okumelana nomthelela futhi ukumelana nokuqala, kodwa futhi kunesibopho esinamandla ne-substrate, futhi kuthuthukisa kakhulu ukumelana nokugqwala, ukumelana namanzi kanye nokushisa okushisayo.

Isimo Sesitoreji:

I-Nano diamond powder kufanele igcinwe endaweni evaliwe, gwema ukukhanya, indawo eyomile.Isitoreji sezinga lokushisa legumbi silungile.

I-SEM: